Fred Werring

Well-known Member

It was the seals. The ones in the MC I'd bought for a mid 60's Chevy truck were not compatible with mineral oil brake fluid and had swollen up.

So I still had the 8700's original master cylinder on the shelf with the aftermarket rebuild kit still in it. The rebuild kit was marketed for Ford 8700 rebuilds so should be compatible with mineral oil brake fluid. The cups didn't look swollen/soft after a year of residual mineral oil sitting in the bores. It had leaked in the original MC when I put the kit in, I blamed it on the severely pitted cylinder bores.

So took the rebuild kit out of the old MC and put it in the new MC. If anybody local would have had a new rebuild kit I'd have bought it, but nobody did, sooo...Actuated the pistons while on the bench, free as can be. Did stretch the springs 1/2" just to do it.

Put it in the tractor, went to bleed the brakes...and after getting fully depressed the pistons don't want to return! They do, eventually, but very slowly. Took me forever to bleed the tractor. Now that I've got the air out of everything, I'll get maybe 1/2" travel on the pistons before they won't go down any more.

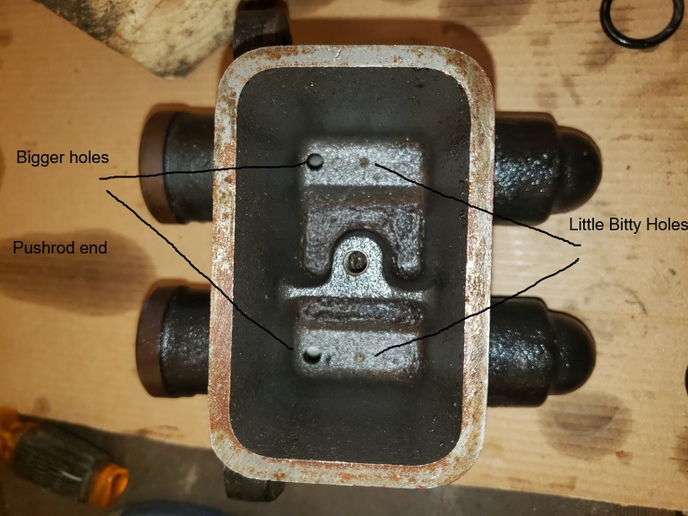

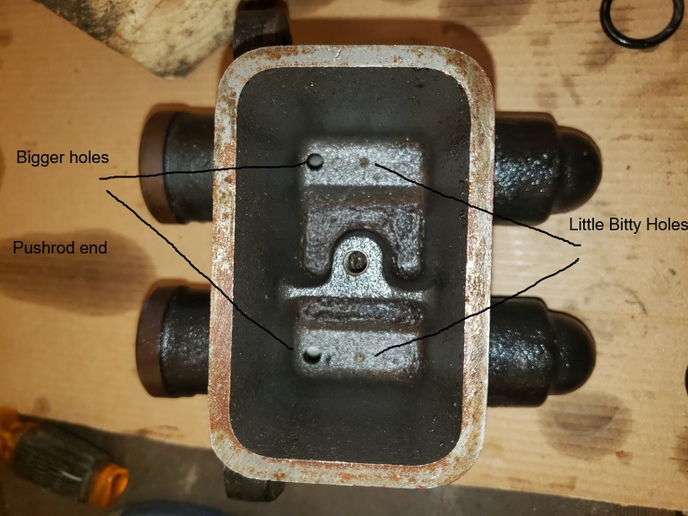

The picture is of the old MC, which is the same dimensionally as the new MC, just with rust. Are those little bitty holes what let the brake fluid back in from the reservoir? Is that why the pistons were so slow to return, trying to get fluid through those holes? What are the bigger holes for? I need somebody to school me on this. Swapped out a lot of MC's on cars over the years, never had these issues. Just like to know what's going on.

Thanks

Fred

So I still had the 8700's original master cylinder on the shelf with the aftermarket rebuild kit still in it. The rebuild kit was marketed for Ford 8700 rebuilds so should be compatible with mineral oil brake fluid. The cups didn't look swollen/soft after a year of residual mineral oil sitting in the bores. It had leaked in the original MC when I put the kit in, I blamed it on the severely pitted cylinder bores.

So took the rebuild kit out of the old MC and put it in the new MC. If anybody local would have had a new rebuild kit I'd have bought it, but nobody did, sooo...Actuated the pistons while on the bench, free as can be. Did stretch the springs 1/2" just to do it.

Put it in the tractor, went to bleed the brakes...and after getting fully depressed the pistons don't want to return! They do, eventually, but very slowly. Took me forever to bleed the tractor. Now that I've got the air out of everything, I'll get maybe 1/2" travel on the pistons before they won't go down any more.

The picture is of the old MC, which is the same dimensionally as the new MC, just with rust. Are those little bitty holes what let the brake fluid back in from the reservoir? Is that why the pistons were so slow to return, trying to get fluid through those holes? What are the bigger holes for? I need somebody to school me on this. Swapped out a lot of MC's on cars over the years, never had these issues. Just like to know what's going on.

Thanks

Fred