john in la

Well-known Member

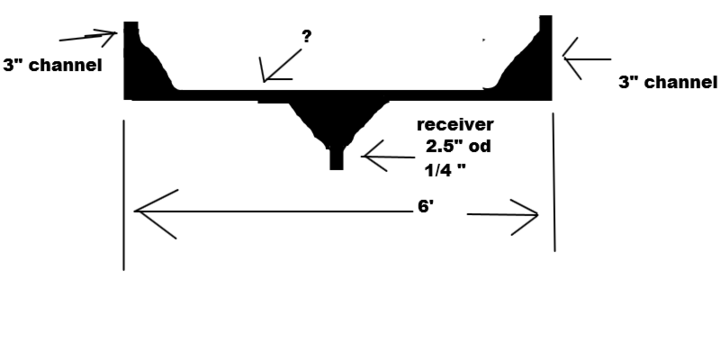

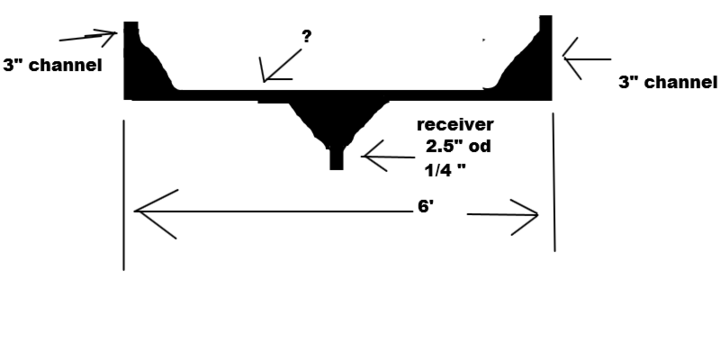

Looking to make a receiver hitch I can put on the back of my camper to pull my boat.

Boat trailer is rated at 3500 lbs but weighs less than that so we can use 3500 lbs safely.

That puts us in the class 2 hitch range.

Frame rails of camper are about 6 feet apart.

I am going to bolt about a 2 foot length of 3 inch channel iron (already have) to the trailer frame rail.

This will allow me to make the hitch bolt on rather that welding it to the frame rails.

I already have a 2.5 inch od 2 inch id receiver tube that is 1/4 inch wall. Its for a class 3 hitch but it fits my ball mounts and I already have it so I will use this.

I also have some 1/4 inch plate that I was going to cut into triangles with the 2 short sides being 1 foot long.

I will use these for gussets on the channel iron sides and also on top and bottom of the receiver tube.

You can look at me crude drawing to get a idea of what I am trying to explain.

My question is.......

Between the 2 pieces of channel iron or frame rails I was thinking about using a 2.5 inch od x 2 inch id x 1/4 inch thick tube.

The length of this tube will be just under 6 feet long.

Is that strong enough?

Is it over kill and I could get away with 2 inch od x 1.5 inch id x 1/4 inch tube?

Thanks

Boat trailer is rated at 3500 lbs but weighs less than that so we can use 3500 lbs safely.

That puts us in the class 2 hitch range.

Frame rails of camper are about 6 feet apart.

I am going to bolt about a 2 foot length of 3 inch channel iron (already have) to the trailer frame rail.

This will allow me to make the hitch bolt on rather that welding it to the frame rails.

I already have a 2.5 inch od 2 inch id receiver tube that is 1/4 inch wall. Its for a class 3 hitch but it fits my ball mounts and I already have it so I will use this.

I also have some 1/4 inch plate that I was going to cut into triangles with the 2 short sides being 1 foot long.

I will use these for gussets on the channel iron sides and also on top and bottom of the receiver tube.

You can look at me crude drawing to get a idea of what I am trying to explain.

My question is.......

Between the 2 pieces of channel iron or frame rails I was thinking about using a 2.5 inch od x 2 inch id x 1/4 inch thick tube.

The length of this tube will be just under 6 feet long.

Is that strong enough?

Is it over kill and I could get away with 2 inch od x 1.5 inch id x 1/4 inch tube?

Thanks