Restoration Story The 1960's promise of white hot technology, to relieve us of the drudgery of everyday work and to replace it with increased leisure time has not materialised just yet....if anything most people are caught up in an ever increasing rat race, wishing that there was at least 36hours in a day!!!. The need for people to escape for periods of relaxation in an increasingly complex and pressured environment takes us into the realm of hobbies. For some it's scaling high mountains for others it's putting paint to canvas, and all of the participants take their respective pastimes seriously taking what ever is required to relax and enjoy.

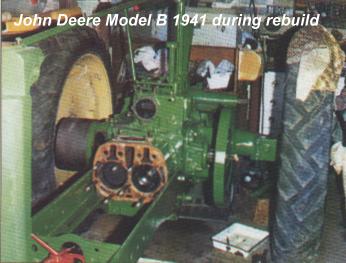

During last autumn (fall) and winter, Bill aquired an unusual 1941 John Deere, model B row crop (all around) from a farm sale in Muckley corner. There was little known history to the machine other than it had been supplied as new in 1942 on lease-lend to Hollyhedge Farm, Brownhills, where it worked its life until around 1970. It disappeared for around 15 years, but reappeared back in the area at Mucking Hall farm in the late 80's. The machine was to be layed up for a considerable time after only a short working life at Mucking Hall, and would only come to light again after the owner passed on and an impliment sale took place in 1997. The reason for the lay up it was found, was due to the machine developing a massive internal water leak. As soon as water was poured into the radiator, It dissapeared into the crank case causing the pistons to hydrolicaly lock!! Still, the engine and tractor were complete. No essentials were absent and all the guages, electrics and tinwork were in good order. Now out in the big world, people will pass you by on the pavement should you need help and pretend you're not there! However in the circle of restoration, assistance and enthusiasm is given freely. Nothing it would appear is too much trouble and if an individual is unable to help, well no doubt he knows some one who can. So Bill, tractor in tow and with boxes of parts managed to get the old B back to the workshop where the arduous task of rebuilding would begin. The engine was disassembled for inspection with the main priority being to trace what was causing such a huge water loss into the crankcase. As a matter of course Bill had the head skimmed and the bores honed out and crack tested by his many associates in the engineering world. After some considerable detection work it was found that one of the pushrod tubes was made of copper and in sound condition whereas the other, made of steel, was rusted through and perforated. This believe it or not, was the cause of the leak. Bill had the tube replaced with a matching copper one, after which the engine reassembly started in earnest, and although time consuming was fairly straight forward. Most of the internal components were rust covered due to the amount of time the machine had stood. On inspection Bill was pleased to find that this was only surface rust and no threat, a new set of piston rings were fitted giving excellent compresion. The big ends were in good condition and refitted with shims found in one of the boxes of spares. The WICO magneto was sound but was sent for overhaul just in case. Owners of old machinery know, with impulse mags a good blue spark is essential for easy starting, as a weak yellow one can be extinguished under compression. Anyway when your swinging over a two and three quarter litre engine by hand you need all the help you can get!!! Turning his attention to the pivots, brakes,clutch etc, Bill found that although some were siezed, they all freed off and operated okay after cleaning and greasing. The massive cast iron radiator was water-tight, but the high and low level thermo-syphon tubes needed welding, a new taper ball race was fitted to the steering mechanism, and as for the body work....well many hours were spent removing the traces of old paint. The castings were then hand painted whilst the metalwork recieved four coats by spray gun. When I called, Bill hadn't started the old girl for quite some time. He showed me to the shed where a large tarpauline covered the beast. In order to start her we first checked everything over, we filled up the radiator with four and a half gallons of water!! this huge amount being required to cool the engine by thermo-syphon as Deere owners know... No water pump is fitted to the large 2.5" diameter flow and return pipes. Spark plugs cleaned and gapped all the usual jobs done we arrived at the point where we were to begin the starting procedure. On this early model there is neither starting handle or electric motor!!, so the method for starting the 2750cc 4.5" bore two-cylinder engine is to flip over the external fly wheel!! Now, as the over head valve engine has a 5.5" stroke, this is far easier said than done!! At least the engine is fitted with de-compressor valves on each cylinder, But due to the strange layout, the valve on the nearside points directly at the poor chap starting it... in this case me!! So as I swung the fly wheel I was sprayed in neat petrol...much to Bill's amusement!! So with petrol on, choke turned, hand clutch engaged but out of gear, I gave several hearty swings on the fly wheel, with a cough and a splutter the massive cast iron pistons did their job and " Johnny popper" burst into life. The compression release cocks were closed tight and she ticked over quite nicely making that lovely twin exhaust note. Bill jumped on board and disengaged the hand clutch, selected a gear and fed in the clutch and the pale green and yellow John Deere gently wheeled out of it's musty hiding place into the watery sunlight....and i have to say she looked resplendant after 463 hours of sweat, tears and lots of Tender Loving Care!!....another nice and happy mending from here in the U.K

We sell tractor parts! We have the parts you need to repair your tractor - the right parts. Our low prices and years of research make us your best choice when you need parts. Shop Online Today. Copyright © 1997-2024 Yesterday's Tractor Co. All Rights Reserved. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Trade Marks and Trade Names contained and used in this Website are those of others, and are used in this Website in a descriptive sense to refer to the products of others. Use of this Web site constitutes acceptance of our User Agreement and Privacy Policy TRADEMARK DISCLAIMER: Tradenames and Trademarks referred to within Yesterday's Tractor Co. products and within the Yesterday's Tractor Co. websites are the property of their respective trademark holders. None of these trademark holders are affiliated with Yesterday's Tractor Co., our products, or our website nor are we sponsored by them. John Deere and its logos are the registered trademarks of the John Deere Corporation. Agco, Agco Allis, White, Massey Ferguson and their logos are the registered trademarks of AGCO Corporation. Case, Case-IH, Farmall, International Harvester, New Holland and their logos are registered trademarks of CNH Global N.V.

Yesterday's Tractors - Antique Tractor Headquarters |